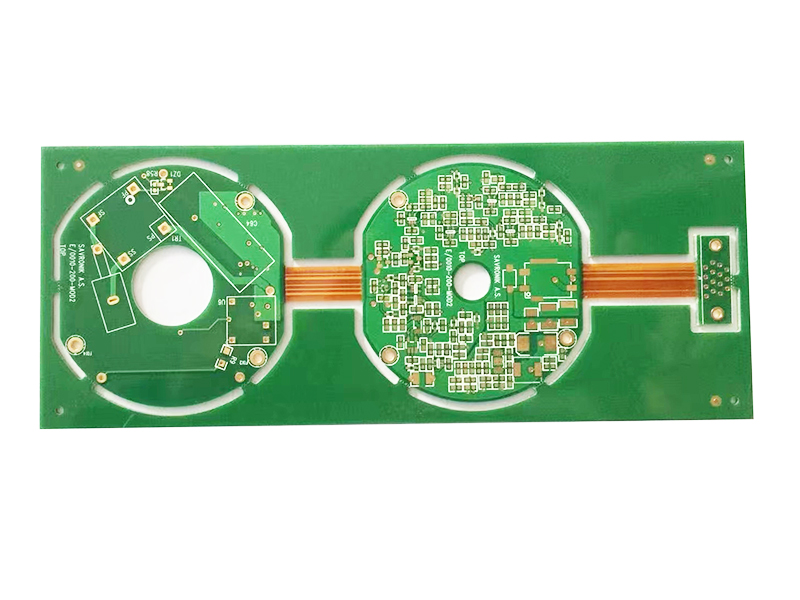

Our Beton Factory has helped customers produce many rigid-flex boards. The following multi-layer rigid-flex board stacks are some of our typical cases.

4 layers Rigid-flex pcb stackup with EMI Shield film

This multilayer Rigid-flex circuit Stackup requires an EMI or RF shielded flex section. This EMI Shield film can achieve very effective EMI and RF shielding without increasing the copper layers cost, and has the reduced cost benefits and thinner flexible structure to increase flexibility.

The flex area cover has multiple selective openings to expose ground circuits. These EMI Shield films have a conductive adhesive so that once laminated, the adhesive extends into the coverlay opening and bonds to the exposed ground, grounding the shield.

This is1+2+1 rigid-flex pcb and combined with 1 rigid circuit, 2 flex circuits and 1 rigid circuits. We can see the shield laminated to the outside of the coverlay in the flex area,which is a more cost-effective solution than adding an extra copper layer, and this stackup greatly increases the flexibility and mechanical bendability of the flex layer.

And the 4 layers rigid-flex board material isFR4+PI+EMI Shield film. Theflexible part is 0.1mm, rigid part can be 0.8-1.6mm and the EMI Shield film is 0.018mm.

6 layers Rigid-flex pcbstandardstackup

A standard rigid-flex PCB design stackup has a symmetrical structure. This type of symmetrical design also allows for impedance control.

As the bellow 6 layers rigid-flex pcb stackup, the flex layer is in the center of the structure, with an even number of layers in the rigid and flex areas. In the two thicker rigid regions, the number of layers is even. In a rigid-flex board example like this one, there can be six layers, or it can go from four to sixteen or more layers. The key point of this rigid-flex circuit stackup is that the flex layer is in the center of the structure.

7layers Rigid-flex PCB stackup with odd number layer

The following is an odd-numbered-layer rigid-flex board stackup. In the manufacture of general rigid-flex boards, the design of rigid-flex circuit boards with uniform layers is required. While an odd number of layers is an uncommon design, our Rigid-Flex factory is manufacturable and has its own set of advantages. This 7 layers Rigid-flex PCB provides great flexibility and reduces costs.

8 layers Asymmetric Rigid-flex PCBstackup

This rigid-flexible PCB structure is an asymmetrical stackup design. Multilayer rigid-flex PCB applications with asymmetric structures are often driven by some very complex impedance requirements, and this type of multilayer rigid-flex PCB exists widely varying dielectric thickness requirements. These may also be caused by the blind via, and this asymmetrical design structure can be allowed to reduce the aspect ratio of the blind via, to improve the unit's manufacturability and reliability.

Because this asymmetrical stackup is an unbalanced build, so in the assembly array may appear some warp and twist. Therefore we need to compress fixture to allow the assembled array to be transported during the assembly process.

This multilayer rigid-flex PCB satckup is an 8 layer rigid-flex PCB with asymmetric. This flex layer is not in the center of the design like a standard rigid-flex stackup and moves down toward the bottom. This type stackup is still in a manufacturable configuration. Besides some warping and twisting might be induced in the assembled array, not any other manufacturing issues.

Other Type multilayer rigid-flex pcb stackup

6 layers Rigid-flex PCB stackup with different flex layers

Other types of multilayer rigid-flex stackups differ in the number of flexible layers between rigid parts. That is, there are three rigid sections, and then there may be three or four flexible layers connecting the first and second rigid sections, but only one or two layers connecting the second and third. There are many configurations of these different flex layer structures, but we recommend using air-gapped flex layer structures for this type of design. This 6 layers Rigid-flex PCB stackup shows different flex layers. There are four Flex layers between the first and second rigid sections, but only two layers of flexibility between the second and third rigid layers. L2 and L3 are flexible layers, although they do extend to the rigid section for routing purposes, these flexilble layers do not span the two sections. The main advantage is that reduced bending part, because the number of interconnects does not need additional layers, and reducing to only two bending layers significantly improves the bending ability of this structure.

This 6 layers Rigid-flex PCB stackup shows different flex layers. There are four Flex layers between the first and second rigid sections, but only two layers of flexibility between the second and third rigid layers. L2 and L3 are flexible layers, although they do extend to the rigid section for routing purposes, these flexilble layers do not span the two sections. The main advantage is that reduced bending part, because the number of interconnects does not need additional layers, and reducing to only two bending layers significantly improves the bending ability of this structure.

This 6 layers Rigid-flex PCB stackup shows different flex layers. There are four Flex layers between the first and second rigid sections, but only two layers of flexibility between the second and third rigid layers. L2 and L3 are flexible layers, although they do extend to the rigid section for routing purposes, these flexilble layers do not span the two sections. The main advantage is that reduced bending part, because the number of interconnects does not need additional layers, and reducing to only two bending layers significantly improves the bending ability of this structure.

This 6 layers Rigid-flex PCB stackup shows different flex layers. There are four Flex layers between the first and second rigid sections, but only two layers of flexibility between the second and third rigid layers. L2 and L3 are flexible layers, although they do extend to the rigid section for routing purposes, these flexilble layers do not span the two sections. The main advantage is that reduced bending part, because the number of interconnects does not need additional layers, and reducing to only two bending layers significantly improves the bending ability of this structure.