3 layers Rigid-flex Circuit Stackup

Rigid-flex board is using a flexible base material and combining it with a rigid base material in different areas to make a circuit board. In the hard-flex joint area, the conductive patterns of the flexible base material and the rigid base material are usually interconnected.

3 layers Rigid-flex Circuit Stackup withsymmetrical structure

The standard rigid-flex PCB structure is 1R+1F+1R. Typically, a standard rigid-flex PCB design has a symmetrical structure. This type of symmetrical design also allows for impedance control.

As the bellow shows, the flexible layer is at the center of the structure, with an even number of layers in the rigid and flexible regions. In this example, there are 3 layers, but it can vary from three to sixteen or more layers. A key element of the design is the flexible layer at the center of the structure.

This is 3 layers rigid-flex circuit stackup(1R+1F+1R). The flex layer use the ED as the base copper. ED is done by electroplating process. ED is formed by separating copper ions in copper sulfate solution by electric current, and then it is completed after anti-oxidation and roughening treatment. ED has strong conductivity and low cost. So sample rigid-flex pcb can use the ED to reduce the cost.

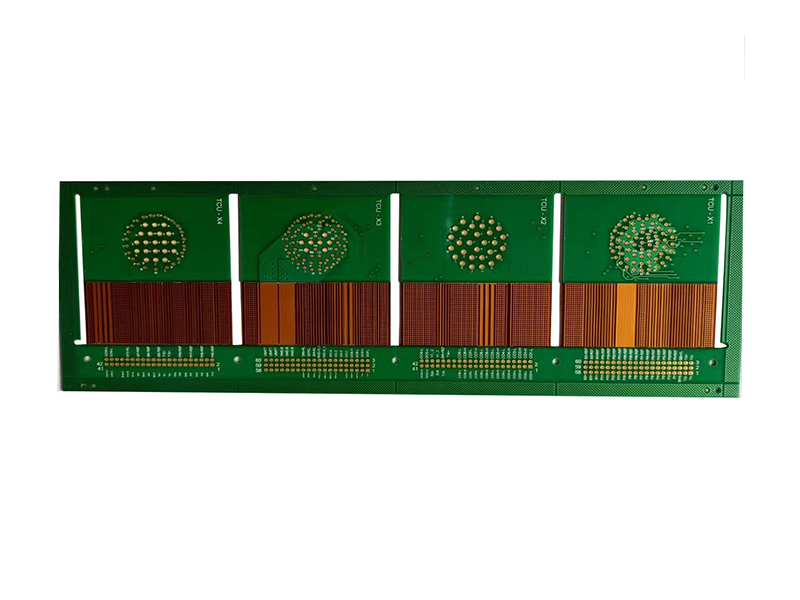

3 layers Rigid-flex Circuit Integrated ZIF Tail Stackup

The rigid-flex circuit boards common stackup also integrates ZIF tails into rigid-flex circuit boards. This integrates ZIF tails don't need to mount the ZIF connector to the rigid board, and also not need a separate flex circuit. This stackup type reduces the need for real estate in rigid board areas. If the component is a high-density design (where real estate will be expensive), or a very thin design, and cannot meet ZIF height requirement.

This rigid-flex circuit with integrates ZIF tails type stackup is also through eliminating connectors and their associated interconnection points in rigid sections to enhance reliability. We have various configurations for your choice. Please see the following 3 layers stackup.

Above 3 layer rigid-flex pcb stackup is a very simple example of a 3 layers rigid-flex PCB integrated ZIF tail structure. The ZIF tail extends to the right which is with an additional polyimide(PI) stiffener to achieve the ZIF finger contact area for the ZIF connector the needed specific thickness.

This stucture can also be combined with multilayer flex circuit. 2 layers, 3 layers, or even 4 layers flex circuits.4 layers flex circuits will be the max actual limitation because this rigid -flex pcb stackup might be tight to fuifill the ZIF thickness requirements. The most common structure is 1 layer flex circuit and 2 layer flex circuits.

Other 3 layers Rigid-flex Circuit Stackup

This is a 1R+2F 3 layers rigid-flex pcb stackup. This circuit board has one rigid areas and two flexible areas. And the flex circuit use the RA as the base copper. The RA material has good bending resistance, good flexibility, the thinner the better the flexibility, and the post-treatment electroplating surface is bright. So make the 3 layers Rigid-flex Circuit have a better flexibility.

This is 2F+1R 3 layer rigid-flex board stackup. It is almost same with above one. 2 layers flexible circuits add a layer rigid circuit. The only difference is the total thickness of rigid-flex board.

The above is the stackup of 3 layers rigid-flex pcb. If you have any questions or demands about 3 layers rigid-flex circuit, please contact me at cathy@beton-tech.com. Our professional engineer will help to solve your rigid flex circuit questions.