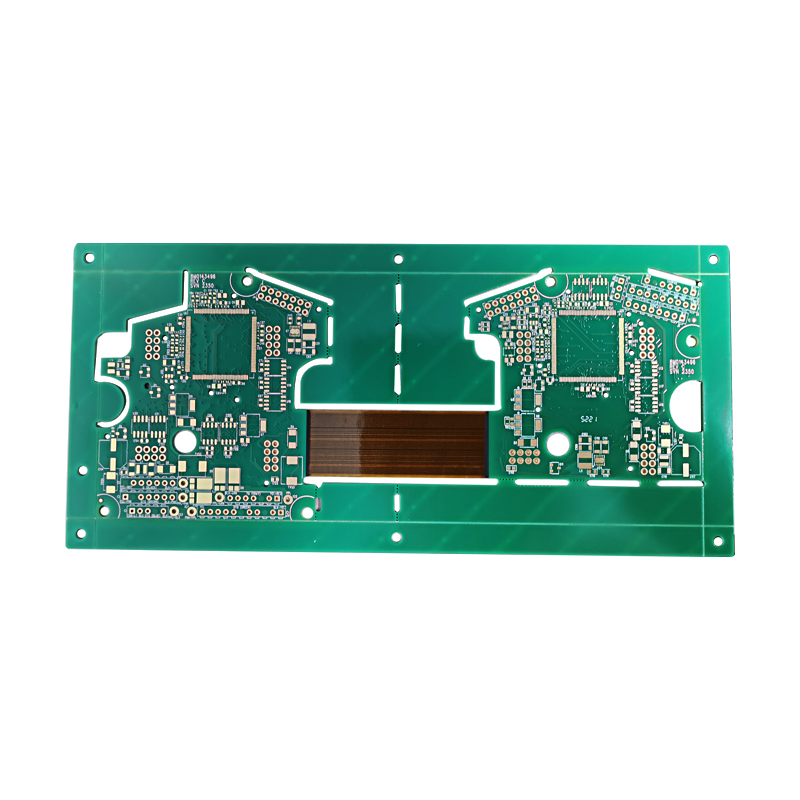

2 Layers Rigid-Flex PCB

Rigid-flex boards are flexible circuits and rigid circuits, which are combined according to relevant process requirements after lamination and other processes to form a circuit board with FPC and Rigid PCB characteristics.

The 2 layers rigid-flex board has FPC and PCB advantage at the same time. Therefore, 2 layers rigid-flex circuit can be used in some products with special requirements. 2 layers rigid-flex PCB has both a certain flexible area and a certain rigid area. 2 layers rigid-flex printed circuit board is of great help to reduce the internal space, reduce the volume of the finished product, and improve the performance of the product.

We offer rigid-flex circuit boards in a variety of features and specifications. Fast delivery is guaranteed as we offer the fastest turnaround times in the industry. Our rigid-flex circuits are durable and able to withstand harsh environments. Our Rigid-Flex Laminate Systems Available is RA Copper, HTE Copper, FR-4, Polyamide, Adhesive.

Get A Quote